Gauging interest in upcoming production run of LDS Pipe Fittings

Moderator: RichardW

-

Jay-Bruce

- (Donor 2022)

- Posts: 514

- Joined: 20 Mar 2019, 00:30

- Location: North East Scotland

- My Cars: BMW 635D

Citroen C5 Tourer (X7) 3.0HDi Exclusive

407 Coupe 2.7vh HDI

206 gti180

206 GranTurisme (Sold)

BX Gti16V (Phase2) - x 246

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

Being honest with y'all, but mainly addressing @Michel's comment about 3d printing a shield for these pipes, the root of the problem with the rear LDS pipes on the suspension stems from the ALUMINIUM union where the fore to aft pipe that runs over the fuel tank meets the tube-hose-tube Flexible Hose Aassembly that goes into the rear firmness regulator, which is the valvebody in the centre of the vehicle with the two spheres on it. To paraphrase Grahem Aerodynamica the ally union on steel pipework "is like an exercise in galvanic corrosion".

If you look at the picture I posted a couple of posts ago, at the bottom of the post with the pictures of the shiny brake calipers, you can see that the square union has virtually consumed the pipe nut, and that the corrosion is absolutely nuts behind the pipe nut. What is not shown in that picture is that the corrosion starts to abate by the time the pipe clears the tank, and it is shiny plastic coated like new as it runs under the floor clipped to the sill. A similar distance of pipe run away from the alli union, in the opposite direction, towards the firmness regulator, the pipe is similarly shiny coated, and the nut hasn't seized on the pupe, unbelievable, but here's a picture.

So... The original pipe was originally coated, the real culprit isn't road spray, it's galvanic corrosion literally stemming from that ALUMINIUM union. There's not really a need to coat the new pipes I'm developing as I'm going to ditch that aluminium union, replace that entire pipeline with galvanically compatible materials.

However, as I love to over-engineer things, I see no reason not to offer customers the option to sleeve the new pipework with heatshrink tubing, so I'll go explore what is the highest ratio heatshrink tubing I can get my hands on, as in a 4:1 tubing would be 10mm ID and shrink down to ~2.5mm ID. I'll see what I can find and get back to you.

If you look at the picture I posted a couple of posts ago, at the bottom of the post with the pictures of the shiny brake calipers, you can see that the square union has virtually consumed the pipe nut, and that the corrosion is absolutely nuts behind the pipe nut. What is not shown in that picture is that the corrosion starts to abate by the time the pipe clears the tank, and it is shiny plastic coated like new as it runs under the floor clipped to the sill. A similar distance of pipe run away from the alli union, in the opposite direction, towards the firmness regulator, the pipe is similarly shiny coated, and the nut hasn't seized on the pupe, unbelievable, but here's a picture.

So... The original pipe was originally coated, the real culprit isn't road spray, it's galvanic corrosion literally stemming from that ALUMINIUM union. There's not really a need to coat the new pipes I'm developing as I'm going to ditch that aluminium union, replace that entire pipeline with galvanically compatible materials.

However, as I love to over-engineer things, I see no reason not to offer customers the option to sleeve the new pipework with heatshrink tubing, so I'll go explore what is the highest ratio heatshrink tubing I can get my hands on, as in a 4:1 tubing would be 10mm ID and shrink down to ~2.5mm ID. I'll see what I can find and get back to you.

- MattBLancs

- Donor 2024

- Posts: 2540

- Joined: 25 Apr 2022, 09:03

- Location: Leyland, Lancashire, UK

- My Cars: Citroen C5 Tourer 2.2 HDi Exclusive 173 6speed (daily family practical wagon),

Peugeot 406 Coupe SE 2.0 137 5speed (& originally auto), (former daily off the road for some TLC)

Peugeot 206 GTi-HDi 1.6 110 5speed (my wife's daily)

Peugeot 306 HDi Dturbo 2.0 90 5speed (long term project to reinstate inner wings, former daily. Too sentimental to let it go!) - x 1336

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

Save you a job / give you some ideasJay-Bruce wrote: ↑15 Mar 2023, 23:36 However, as I love to over-engineer things, I see no reason not to offer customers the option to sleeve the new pipework with heatshrink tubing, so I'll go explore what is the highest ratio heatshrink tubing I can get my hands on, as in a 4:1 tubing would be 10mm ID and shrink down to ~2.5mm ID. I'll see what I can find and get back to you.

6.4mm, 2:1, clear, 5m, £1.08

https://cpc.farnell.com/pro-power/15038 ... dp/CB09717

Lots of colours,

Not found any 4:1 shrink ratio stuff on there as yet.

Is some 10m lengths available too

- darbuck

- Donor 2023

- Posts: 1036

- Joined: 25 May 2014, 16:45

- Location: Offaly, Ireland.

- My Cars: 2008 Citroen C5 X7 Tourer VTR+ (138 BHP)

2007 Nissan Primera P12 1.6 T-Spec (110BHP)

2003 Citroen C5 Estate level 2 (110 BHP) 2.0 HDI

2001 Nissan Maxima QX 2.0 V6 - x 143

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

I don't see any reason to coat the new pipework as it shouldn't corrode if you use these materials. The aluminium block could be cleaned up and a lacquer applied to the mating surfaces to insulate against any galvanic issue.

Darren

- KennyW

- Donor 2024

- Posts: 2507

- Joined: 17 Jan 2006, 21:22

- Location: Letham, Fife

- My Cars: Current Citroen's

C5 x7 2010

SWMBO C3 2012

Previous Citroen's

Xantia 2.0 90hp estate

Xantia 1.9 TD estate - x 132

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

Jay,

My C5 is in the exact same state and I'm praying I won't have to touch it. They look horrendous but when I changed my front to rear pipe after the leak the union broke with no fuss.

These regulators will be like hen's teeth soon. I look at the securing nuts for the regulator and they look more like blobs of rust rather than nuts.

Just replaced the rear height sensor and had the same problem with the support bracket. Yet a few inches away the triangle pyramid nuts were in excellent condition.

Kenny

My C5 is in the exact same state and I'm praying I won't have to touch it. They look horrendous but when I changed my front to rear pipe after the leak the union broke with no fuss.

These regulators will be like hen's teeth soon. I look at the securing nuts for the regulator and they look more like blobs of rust rather than nuts.

Just replaced the rear height sensor and had the same problem with the support bracket. Yet a few inches away the triangle pyramid nuts were in excellent condition.

Kenny

C5 x7 2.0 HDi 160 hp Estate exclusive, the newbie

Xantia 2.0 Hdi 90hp 1999 only 189,000 and rising!!!!!!! Moved on to a new home

C3 1.4 petrol (SWMBO)

Xantia TD 1.9 Mk 2 Estate LX 1998 model over 210,000 miles now and still rising!!!!!!!!!!!!! now deceased 17/12/2010.

Xantia 2.0 Hdi 90hp 1999 only 189,000 and rising!!!!!!! Moved on to a new home

C3 1.4 petrol (SWMBO)

Xantia TD 1.9 Mk 2 Estate LX 1998 model over 210,000 miles now and still rising!!!!!!!!!!!!! now deceased 17/12/2010.

-

Jay-Bruce

- (Donor 2022)

- Posts: 514

- Joined: 20 Mar 2019, 00:30

- Location: North East Scotland

- My Cars: BMW 635D

Citroen C5 Tourer (X7) 3.0HDi Exclusive

407 Coupe 2.7vh HDI

206 gti180

206 GranTurisme (Sold)

BX Gti16V (Phase2) - x 246

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

I've been theory crafting on that one in the background, I'll bring you up to speed with my thoughts on that one. From what I can gather, the BHI does the height control internally via it's solenoid valves diverting suspension fluid to the reservoir to lower an axle, or lining up the pump to the firmness regulator and supplying pressure to raise the height... The reason our car's back end sinks to the bump stops is, that for reason I cannot fathom, Citroen have the system engineered to use a solenoid valve controlling suspension pressure as pilot fluid to operate a shuttle valve that isolates or connects the middle comfort spheres with the suspension struts, credit to tramotana.hu for their excellent diagram that I'm about to reference:

What happens with our system is the valve shuttle in the bottom left "control from computer" sticks in a position that permits communication from the struts, all four rear spheres, back to the tank via the return line, and would look like this:

Once again I'm standing on the shoulders of the giant that is Tramontana.hu as I've based this failure mode diagram on his hard/soft mode diagram, which I've also borrowed for this conversation.

Basically what happens in the failure mode is the red shuttle controlled by the electro solenoid from the BHI gets stuck and leaves an open path from suspension pressure to simultaneously bypass the solenoid valve's shuttle, energise the pilot-operated valve to open communication with the centre comfort spheres and bypass the shuttle to go to return. And thus, as long as there's fluid in the back axle cylinders, it's pressure opens the comfort regulator pilot valve and creates it's own path to tank.

Given the functionality of this valve block, I genuinely do not see why they didn't simply make the solenoid valve's shuttle isolate/open to the comfort spheres directly, maybe other than to use cheaper solenoids? So I'm exploring two options, the cheapest, the most ghetto solution is to do away with the firmness regulator, and dumb the system down to having essentially a Tee piece there, like Hydractive 3 rather than 3+.

The other, less ghetto, but more complex & consequently costly solution is to make a new valve block whereby the BHI sends an electrical signal to a solenoid valve that opens or closes off communication with the comfort spheres. This approach will allow do away with the pilot-operated valve, and its associated return line, removing the path for fluid to leave the suspension cylinders via the firmness regulator, causing the droop we are getting plagued with.

Sticking with the tramontana graphics style, what I'm suggesting would look like this in Soft Mode:

And like this in Hard Mode:

By doing away with the return line and pilot valve, there is no way for fluid to escape the struts and get back to tank, so a car with this sort of valve would never droop. I've got a rough notion in my head to reuse the original arrowhead shaped block the spheres mount into on the rear firmness regulator, make a 4 way tee connecting the aforementioned arrowhead, via a solenoid valve, to cylinder hoses, and the BHI supply line. The solenoid valve I use will almost certainly going to need more power than the ECU signal, so it'd be connected by a relay to a 12v supply, which ends up looking like this powerpoint sketch:

Basically, the signal from the BHI's electronics would be the trigger signal for the relay (coil size would be selected to match signal characteristics) this would then allow power to flow from the fused 12v supply to open or close the solenoid valve engaging soft or hard mode as per the BHI's intentions, easy set up by switching the NC/NO contacts on the relay to get the desired effects. This would give us robust, serviceable, functional hydractive 3+ mode switching with no leak path and thus no back bumper on floor failure mode, because there is no pilot returnline for the fluid in the suspension cylinders to sneak down. Your thoughts?

PS: All this could have went away if Citroen had made the height control algorithm closed loop, and upon seeing the back sitting low, line up the valves, fire up the pump and raise the back end.

- darbuck

- Donor 2023

- Posts: 1036

- Joined: 25 May 2014, 16:45

- Location: Offaly, Ireland.

- My Cars: 2008 Citroen C5 X7 Tourer VTR+ (138 BHP)

2007 Nissan Primera P12 1.6 T-Spec (110BHP)

2003 Citroen C5 Estate level 2 (110 BHP) 2.0 HDI

2001 Nissan Maxima QX 2.0 V6 - x 143

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

Hi Jay if it fails like you have shown would that not stop the system from depressurising fully, and also when you try to change a sphere allow significant fluid loss due to no non return function of the solenoid. From looking at the diagrams it looks to me like Citroen designed it to fail closed to avoid this.

Darren

-

Jay-Bruce

- (Donor 2022)

- Posts: 514

- Joined: 20 Mar 2019, 00:30

- Location: North East Scotland

- My Cars: BMW 635D

Citroen C5 Tourer (X7) 3.0HDi Exclusive

407 Coupe 2.7vh HDI

206 gti180

206 GranTurisme (Sold)

BX Gti16V (Phase2) - x 246

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

Assuming Tramontana's diagrams are accurate in the functionality they describe, even though the physical arrangement of the valve looks nothing like the diagrams, but they never do, the failure mode can't be a gazillion miles away from what I've described. Have a look at this post in the C6 owners club, http://c6owners.org/plugins/forum/forum ... hp?2638.30 where CruiserPhil (Phil C) has a dive into the firmness regulator's innards, you might see something I'm missing?

-

Jay-Bruce

- (Donor 2022)

- Posts: 514

- Joined: 20 Mar 2019, 00:30

- Location: North East Scotland

- My Cars: BMW 635D

Citroen C5 Tourer (X7) 3.0HDi Exclusive

407 Coupe 2.7vh HDI

206 gti180

206 GranTurisme (Sold)

BX Gti16V (Phase2) - x 246

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

Came up with a new approach for these blerry fittings, rather than try and piece three things together and end up struggling with the width of the flare at the bottom of the pipe, and struggling even more string to shoehorn an oring in there,I came up with the idea of making a nipple that's an exact copy of the citroen gubbins on oneside to screw into the port, and on the other side it's got a m10x1 brake pipe nipple on it. Here is a screenshot:

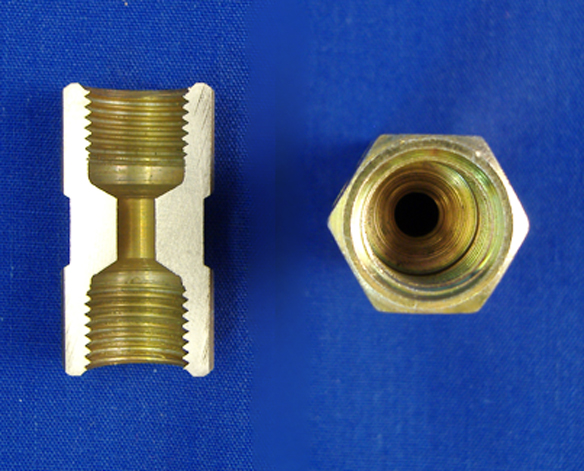

The LDS gubbins at the bottom is an amalgamation of the tube end, the o-ring, the washer, the cone and the tube nut in one body, the top end is modelled off of a conventional brake pipe fitting, m10x1.0mm male male joiner, like this:

My machinist is excellent, so on my fittings, you won't have the striations on the tapered mating face that can be seen in the picture above.

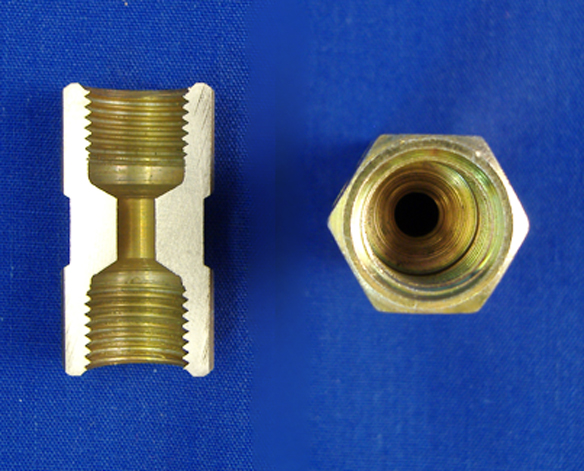

This new decision to come out to an m10 flare would give you options for how to fit them, you could either use a female/female joiner on the nipple, like this:

...and run in with a conventional male pipe nut and a single 45° flare, but best with a 45° double flare; or you could use it as it's designed to work; with a female brake pipe nut with the 45° flare on the tubing which would keep the overall fitting shorter, but might be less tolerant of imperfectly flared pipes...

In the first picture, the screenshot from my CAD, repeated above, you can see the obvious o-ring groove at the bottom, I'm debating sticking a couple of extra o-rings on the nipple at the points denoted with the yellow line. Basically, I'd put another o-ring on the LDS end on the chamfered face as a secondary seal, and also one on the cone in the m10x1.0 brake fitting to help seal the flared brake-pipe-styled tubing end against the cone. I've seen this sort of thing for JIC fittings designed to be used with flared tubing:

Do you guys want an o-ring in that location on the flarepipe mating cone?

Technically if we can get these nipples to seal in the LDS end, it'd be on whoever is flaring the "brake pipes" to do the flares well well to get a seal, but I'm trying make sure this is a pain free solution for y'all to work with, so was considering the extra o-ring to make it easier for y'all to get a seal on it. So what do you think, should I put an o-ring on the brake fitting style cone?

My machinist is excellent, so on my fittings, you won't have the striations on the tapered mating face that can be seen in the picture above.

This new decision to come out to an m10 flare would give you options for how to fit them, you could either use a female/female joiner on the nipple, like this:

...and run in with a conventional male pipe nut and a single 45° flare, but best with a 45° double flare; or you could use it as it's designed to work; with a female brake pipe nut with the 45° flare on the tubing which would keep the overall fitting shorter, but might be less tolerant of imperfectly flared pipes...

In the first picture, the screenshot from my CAD, repeated above, you can see the obvious o-ring groove at the bottom, I'm debating sticking a couple of extra o-rings on the nipple at the points denoted with the yellow line. Basically, I'd put another o-ring on the LDS end on the chamfered face as a secondary seal, and also one on the cone in the m10x1.0 brake fitting to help seal the flared brake-pipe-styled tubing end against the cone. I've seen this sort of thing for JIC fittings designed to be used with flared tubing:

Do you guys want an o-ring in that location on the flarepipe mating cone?

Technically if we can get these nipples to seal in the LDS end, it'd be on whoever is flaring the "brake pipes" to do the flares well well to get a seal, but I'm trying make sure this is a pain free solution for y'all to work with, so was considering the extra o-ring to make it easier for y'all to get a seal on it. So what do you think, should I put an o-ring on the brake fitting style cone?

- MattBLancs

- Donor 2024

- Posts: 2540

- Joined: 25 Apr 2022, 09:03

- Location: Leyland, Lancashire, UK

- My Cars: Citroen C5 Tourer 2.2 HDi Exclusive 173 6speed (daily family practical wagon),

Peugeot 406 Coupe SE 2.0 137 5speed (& originally auto), (former daily off the road for some TLC)

Peugeot 206 GTi-HDi 1.6 110 5speed (my wife's daily)

Peugeot 306 HDi Dturbo 2.0 90 5speed (long term project to reinstate inner wings, former daily. Too sentimental to let it go!) - x 1336

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

I've not seen an O-ring in a position like on the JIC fittings pictured, what cross section are the O-rings pictured?, as look tiny! I'd be concerned it could be more trouble than it's worth.

The standard Citroen setup I presume allows slip between where the O-rings are and the threaded second, so eliminating that potential is only thing I would worry about with your proposed one piece fitting.

I'm not sure if the lack of slip would give a hard time for the O-ring on assembly (but nowt a dab of red rubber grease wouldn't eliminate?) And/Or else increase the torque required to break the fitting loose from whatever it has been screwed into for disassembly maybe years later.

However, if installing one of your proposed fittings, you could split it at the M10x1.0 instead. So no need to disturb the Citroen fitting replacement once installed.

Given that, would it be better to aim to add a thread locking / sealant at the original connection and do away with the considerations of extra O-rings?

Just thinking aloud, and it is nice to see your developments on this too, thanks

The standard Citroen setup I presume allows slip between where the O-rings are and the threaded second, so eliminating that potential is only thing I would worry about with your proposed one piece fitting.

I'm not sure if the lack of slip would give a hard time for the O-ring on assembly (but nowt a dab of red rubber grease wouldn't eliminate?) And/Or else increase the torque required to break the fitting loose from whatever it has been screwed into for disassembly maybe years later.

However, if installing one of your proposed fittings, you could split it at the M10x1.0 instead. So no need to disturb the Citroen fitting replacement once installed.

Given that, would it be better to aim to add a thread locking / sealant at the original connection and do away with the considerations of extra O-rings?

Just thinking aloud, and it is nice to see your developments on this too, thanks

-

Jay-Bruce

- (Donor 2022)

- Posts: 514

- Joined: 20 Mar 2019, 00:30

- Location: North East Scotland

- My Cars: BMW 635D

Citroen C5 Tourer (X7) 3.0HDi Exclusive

407 Coupe 2.7vh HDI

206 gti180

206 GranTurisme (Sold)

BX Gti16V (Phase2) - x 246

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

Hi Matt, thanks for your thoughts, I think my previous post also ended up as a thinking aloud session WRT the additional orings. Even though I proposed them, they would be a bit of a pain for me, but I'd have taken the hit if it was beneficial for y'all? Really, short of making a 3 part fitting that would be more expensive and less strong, I think we're going to have to live with greasing the o-rings. I don't want to go down the Russian route of providing an inappropriate fitting that requires a tonne of thread sealant to make it work.

- darbuck

- Donor 2023

- Posts: 1036

- Joined: 25 May 2014, 16:45

- Location: Offaly, Ireland.

- My Cars: 2008 Citroen C5 X7 Tourer VTR+ (138 BHP)

2007 Nissan Primera P12 1.6 T-Spec (110BHP)

2003 Citroen C5 Estate level 2 (110 BHP) 2.0 HDI

2001 Nissan Maxima QX 2.0 V6 - x 143

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

Hi Jay, firstly very good design and better to think out loud it helps to solve problems and purge any misgivings. I agreed with Matt the idea of a secondary seal on a threaded fitting would probably result in complications such as failure by damaging the o-ring during the the threading in process. The only suggestion I would have is you could bench test with and without. To me your at the prototype phase and need to determine efficacy. I hope it helps.

Darren

-

Jay-Bruce

- (Donor 2022)

- Posts: 514

- Joined: 20 Mar 2019, 00:30

- Location: North East Scotland

- My Cars: BMW 635D

Citroen C5 Tourer (X7) 3.0HDi Exclusive

407 Coupe 2.7vh HDI

206 gti180

206 GranTurisme (Sold)

BX Gti16V (Phase2) - x 246

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

Thanks for the compliment! I also really appreciate the feedback, I'm taking on board what you guys have said and the additional o-rings are out. There is a simpler solution for a backup seal, PTFE tape the threads I've highlighted below, or treat them to a couple of drops of my favourite thread sealer, Loctite 542 hydraulic thread sealant.

- darbuck

- Donor 2023

- Posts: 1036

- Joined: 25 May 2014, 16:45

- Location: Offaly, Ireland.

- My Cars: 2008 Citroen C5 X7 Tourer VTR+ (138 BHP)

2007 Nissan Primera P12 1.6 T-Spec (110BHP)

2003 Citroen C5 Estate level 2 (110 BHP) 2.0 HDI

2001 Nissan Maxima QX 2.0 V6 - x 143

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

Yeah PTFE will give a good seal without risking over or under torquing. I would prefer it to a liquid seal but each to their own.

Darren

-

OnlineGiveMeABreak

- Forum Admin Team

- Posts: 37444

- Joined: 15 Sep 2015, 19:38

- Location: West Wales

- My Cars: C3 Aircross SUV HDi Flair Peperoncino Red (The Chili Hornet)

C5 X7 2.0 HDi Exclusive Mativoire Beige (The Golden Hornet)

C3 1.6 HDi Exclusive Aluminium Grey (The Silver Hornet)

C5 MK II 2.0 HDi Exclusive Obsidian Black

C5 MK I 2.0 HDi SX Wicked Red

Xantia S2 2.0 HDi SX Hermes Red

C15 Romahome White

XM 2.0 Turbo Prestige Emerald Green Pearlescent

XM 2.0 Turbo Prestige Polar White

XM 2.0 SX Polar White

CX 20 Polar White

GS 1220 Geranium Red

CX 2.4 Prestige C-Matic Nevada Beige

GS 1000 Cedreat Yellow - x 5742

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

A post that may be of interest to some of you from a new member:

viewtopic.php?p=750080#p750080

We've let this go as it's of specific relevance to C5 and C6 owners given the lack of spares.

viewtopic.php?p=750080#p750080

We've let this go as it's of specific relevance to C5 and C6 owners given the lack of spares.

Please Don't PM Me For Technical Help

Marc

Marc

- MattBLancs

- Donor 2024

- Posts: 2540

- Joined: 25 Apr 2022, 09:03

- Location: Leyland, Lancashire, UK

- My Cars: Citroen C5 Tourer 2.2 HDi Exclusive 173 6speed (daily family practical wagon),

Peugeot 406 Coupe SE 2.0 137 5speed (& originally auto), (former daily off the road for some TLC)

Peugeot 206 GTi-HDi 1.6 110 5speed (my wife's daily)

Peugeot 306 HDi Dturbo 2.0 90 5speed (long term project to reinstate inner wings, former daily. Too sentimental to let it go!) - x 1336

Re: Gauging interest in upcoming production run of LDS Pipe Fittings

That's what I was meaning but failing to clearly communicate, stick some sealant or good old PTFE on those threads.

The more I think about it, the more I think the O-ring with a dab of red rubber grease would likely survive installation. Just make the O-ring single use I'd say.

As others said, prototype territory, and good to post up ideas to "kick them around a bit" (note: this is different to "kick them to bits" )

)

The more I think about it, the more I think the O-ring with a dab of red rubber grease would likely survive installation. Just make the O-ring single use I'd say.

As others said, prototype territory, and good to post up ideas to "kick them around a bit" (note: this is different to "kick them to bits"